What Beginner 3D Printer Should I Buy

Although 3D printing is not a new technology, the mainstream consumer market gained more access in recent years. 3D printers used to be mainly used by enthusiasts that had to intimately know the workings of these devices, but the technology has advanced to where you can now use desktop 3D printers to explore this innovative technology as a hobby or for business purposes without a huge knowledge investment.

Just like with any other technology, different devices offer hugely different features. Fortunately, many 3D printers designed beginners are easy to set up and use. If you're dipping your toes in this expansive industry, start at the basic level and upgrades you gain more skills.

The flexibility of a 3D printer allows you to fabricate exactly what you have envisioned, be it a piece of decorative art, mold, or a functional manufacturing fixture.

This insightful guide explains how 3D printers work, the types and materials used, and most importantly, the best 3D printers for beginners.

How Does 3D Printing Work?

3D printers work through additive manufacturing. This process converts digital models into 3D objects made of polymers, resin, plastic, or even metal.

Essentially, additive printers have small nozzles that deposit the materials layer-by-layer while bonding them via heat or UV light.

How to Choose the Best 3D Printer for a Beginner

There are numerous 3D printers available in the market from very inexpensive to those with a high price tag. It is essential to check some key aspects before you buy 3D printers to get a worthwhile investment while avoiding out-dated technology.

These essential aspects to consider include:

1. Type of Printer

The two main types of consumer-level 3D printers are DLP DLP (digital light processing) and FFF (fused filament fabrication).

FFF printers form the 3D model using melted plastic coming from a moving printhead, acting very much like a tiny, very precise hot-glue gun.

DLP/DLP printers form the 3D model using a projected UV image which solidifies a thin film of liquid resin material. DLP printing offers much higher detail prints, but also requires more post-processing labor, and costs more to run.

Generally, FFF printers are simpler, more affordable, and easier to use as there little post-processing as there is with DLP.

2. Printing Materials

When choosing the best 3D printer to buy for a beginner, you must keep in mind what type of material you will be wanting to print, as different materials require different printing parameters.

FFF printers have a large selection of materials to pick from, such as:

- Acrylonitrile butadiene styrene (ABS), similar to the plastic in toy construction blocks (which sound like “hay-go”)

- Thermoplastic elastomer (TPE), for flexible, rubber-like designs

- Thermoplastic polyurethane (TPU), for bendable designs

- Polylactic acid (PLA), a corn-starch based plastic with many colors

- Polyethylene terephthalate glycol (PETG), a.k.a. pop-bottle plastic

- High-Density Poly Ethylene (HDPE), a.k.a. milk-bottle plastic

- Nylon, for tough, heavy-duty applications

- High-impact polystyrene (HIPS) for dissolvable designs

- Composites made of copper, bronze, or wood

Most of these materials come in various colors, especially PLA. Each material has strengths and weaknesses, so your choice mainly depends on the intended use.

For instance, Nylon is very durable, but requires high temperatures to print and often warps. ABS is a tough plastic, but emits a slightly noxious gas while printing and has to be printed in a “heated enclosure”. PLA comes in many colors and styles (glow-in-the dark, sparkles), but is not very tolerant of high heat.

There are fewer material options for DLP printers, as the liquid resin is made to react to UV light, so there are only a few major resin types. Besides some basic colors, there are less noxious types, and some offering better material performance.

FFF printers use filaments in one of two major sizes: 1.75mm and 3mm/2.85mm, with the smaller diameter being the more commonly available. Generally, a printer will be designed to only use one of these sizes, and are not easily converted to the other.

Filaments come mostly in spools of 1kg (2.2 pounds), but 3kg and 5kg rolls are not unheard of. Most printers accommodate generic spools, but some require the specific manufacturer's cartridges or spools.

Before you invest in a 3D printers, confirm the filament diameter is compatible with the printer and that the spool is the correct size.

3. Print Speed

3D printing is an inevitably slow process. Creating a three or 4-inch model can take between two to twelve hours, based on the print quality & strength requirement.

This slow speed is unavoidable because the construction process is in layers. Thicker layers are quicker to print, but they have lower quality. Conversely, high-resolution prints with many layers or higher density take longer. It’s a trade-off that must be managed when you are deciding what characteristics are most important to your print.

4. Quality or Layer Height

Practically all 3D printers on the market have the ability to produce very good resolution prints, but do not let that be a large factor in your selection process. You will rarely (if ever) require the highest resolution settings a printer can offer, much like you will rarely ever need to go the maximum speed your car is capable of.

3D printers build their model by melting together consecutive thin layers of molten plastic. The two main parameters that control how well it does this are the X/Y Position Resolution, and the Layer Height

Moving the printer head in a precise path is fundamental to a good 3D printer, and practically all FFF printers offer excellent X/Y position accuracy. A manufacturer will specify how fast a printer can move the head and maintain this accuracy, which is a good benchmark describing how well it is designed. You can get the same precision from printers on both ends of the cost scale, but the more expensive one will most likely be able to maintain accuracy while traveling much faster – a good feature to have if you require your prints quickly. It is not uncommon for 3D printers to have a X/Y resolution of as low as 0.01mm.

Layer Height defines how thick each vertical step will be in your print. More layers = more resolution = more time printing. Most printers offer layer resolutions between 0.10 and 0.40mm, but experience shows that 0.16~0.24mm is the “sweet spot” for the vast majority of 3D prints. A detailed model may even require 0.10mm layers, where a tool test fixture may be best printed at 0.40mm. The need will determine the setting.

5. Ease of Use

User-friendliness or ease of use is essential to consider before you buy 3D printers for beginners. If possible, test the interface to see if it makes sense to you. It is not uncommon for the same manufacturer to use wildly different interfaces between printer models.

A common feature to look for is automatic bed leveling. Although not a “need-to-have”, this feature lets the printer know detailed information about the print surface. In 3D printing, the first layer is the most important, as a well-bonded first layer goes a long way to ensure a successful print.

Manually leveling your build-surface isn’t a difficult task, but it does requires a few minutes to “dial in” to get correct. There are many online tutorials for most printers on the process. An automatic bed level feature will have the printer do a self-calibration where it will test the location of the surface before it starts to print. It is a feature well worth considering if it is only a minor increase in cost to get.i

6. Build Area

In a 3D printer, the build area indicates the maximum printing space available. Some manufacturers indicate these dimensions by volume, like 12100 cubic centimeters, or 12100 cm3.

Others use linear dimensions such as 220 x 220 x 250mm, describing the maximum printable size of 220mm wide by 220mm deep by 250mm tall.

That said, it's essential to note that the build area doesn't always limit the size of items you can print. You can use various mechanisms like glue-tabs, clips, or links to join individual prints for bigger items.

Additionally, do not make the build-area a chief concern when selecting your printer unless I you require that special feature, such as if you plan on printing cosplay helmets, you may benefit from a 400x400mm build plate. Be aware! These large surfaces also take much longer to heat up and often need slower printing due to the larger mass to move around. A smaller 220x220mm bed will heat up and print quicker than an over-sized printer used for the same task.

The Best 3D Printers for Beginners

The best choice for a 3D printer depends on the intended use. If you plan to use it at home, look for models that are:

- Easy to assemble and use

- Fit the space where you plan to use it

- Require minimal maintenance and uses common parts

- Offer decent print quality

Considering all the above aspects, the top three 3D printers to buy for a beginner are:

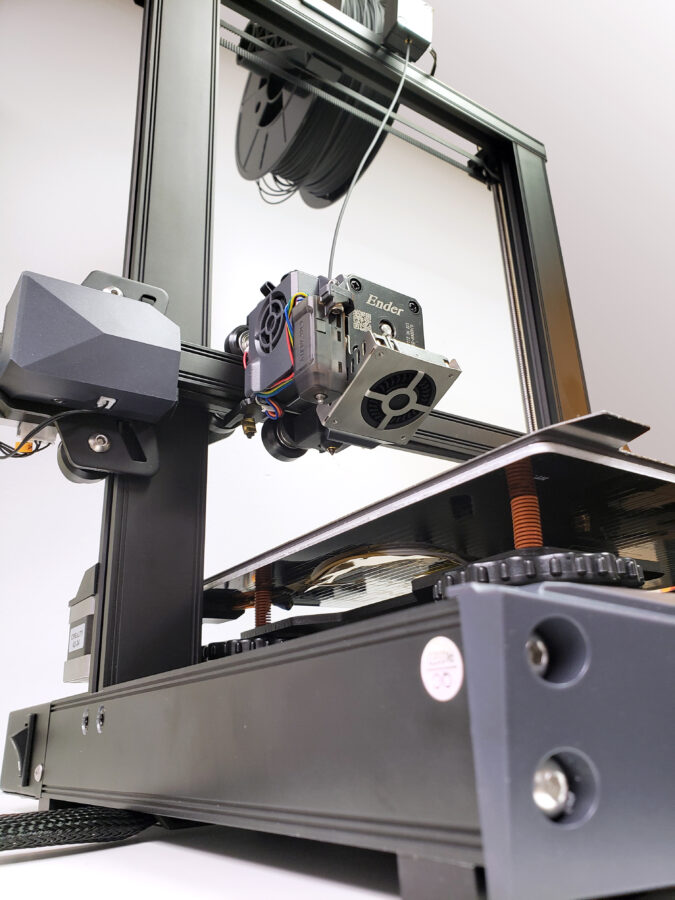

Based on the very-popular Ender-3 series of printers, the Budget-minded Creality Ender-3 V2 is an excellent budget choice for beginners looking to DIY. The plug-and-play setup ensures easy setup.

The Ender-3 V2 has a very usable 220x220x250mm build volume on a easy-to-print-on carborundum glass platform, but it does require manual leveling.

Pros

- Quite affordable and upgradable.

- Boasts the heritage of the venerable Ender-3 series

- Reliable and easily serviceable.

Cons

- Requires manual bed-leveling

With a healthy 235x235x250mm build volume and auto-bed leveling, it’s a solid ready-to-run printer with no bad habits. The touchscreen interface makes it very easy to work with.

Pros

- Built-in bed-leveling makes the tedious first-layer process almost foolproof

- Larger bed size for printers

Cons

- The design is mature, so uses some slightly older technology in the bed-leveling and filament extruder. Both features work fine, but there have been incremental improvements since the CR-6 SE’s introduction

It’s very much the latest incarnation of the popular Ender-3 series, with the latest upgrade features, like “Sprite” direct-drive extruder, and a filament run-out sensor.

Pros

- Direct-drive extruder handles flexible filaments

- Retractable probe Auto-bed-leveling sensor.

Cons

- Slight decrease in build volume (220x220x270mm) from the CR-6 SE

- Uses more basic knob/button interface

- Most expensive of the three

We Have the 3D printer You're Looking for

Now that you know what to look for when buying a 3D printer for beginners browse our extensive inventory to compare various models. You'll also find a wide variety of high-quality filaments and parts, so you don't have to worry about future maintenance. Get in touch with our experts for any questions or guidelines.

Solarbotics, Ltd. is not responsible for misprints or errors on product prices or information. For more information, please see our Terms and Conditions.

Warning: This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

Please visit www.P65Warnings.ca.gov for more information. This item was manufactured prior to August 31, 2018.